Idaho Tree Planting

In 1968, a diverse group of 19 organizations from Eastern Washington, Northern Idaho, and Western Montana, including PotlatchDeltic, formed the Inland Empire Tree Improvement Cooperative (the IETIC). This group joined together to apply classical plant breeding techniques to native conifer species, which are important for commercial reforestation and ecosystem restoration. Foresters from the 19 organizations took to the forest to select parent trees (or “plus trees”). These plus trees were chosen for their characteristics that made them stand out from other trees in the stand. Those characteristics included faster growth, good form and resistance to insects and disease. Once these plus trees were identified, seed was collected from them and planted in test sites. In 1974, the IETIC established its first progeny tests and since then, more than 120 field tests of more than one million seedlings have been established. These field tests have been the proving grounds for the thousands of parent trees selected by foresters across the forested landscape. From these test sites, cuttings from the superior growing offspring are grafted onto 2-year-old seedling root stock. The seedlings are then grown in a greenhouse for about six months until the graft is healed, and the trees can be planted in the seed orchard. These grafted seedlings are genetically identical to the offspring of the original plus trees.

As a member of the IETIC, PotlatchDeltic was able to utilize the same genetic material from top ranking trees and clone them by grafting. This process was used by PotlatchDeltic personnel who had the foresight to establish the 40-acre Cherrylane seed orchard located near Lewiston, Idaho over 40 years ago. It was a pioneering approach to environmental stewardship and a substantial commitment to ensuring a reliable and consistent supply of improved seed of commercially important native tree species of the Northern Rockies. Seeds produced from this process are not genetically modified and we are committed to exclude genetically modified seedlings or wood fiber throughout our operations.

The seed orchard continues to be managed by tree improvement and silviculture experts and produces enough seed for 90% of the seedlings planted on our Idaho timberlands. The seed orchard is used as the tree breeding orchard for the IETIC and to increase seed production of the highest performing trees.

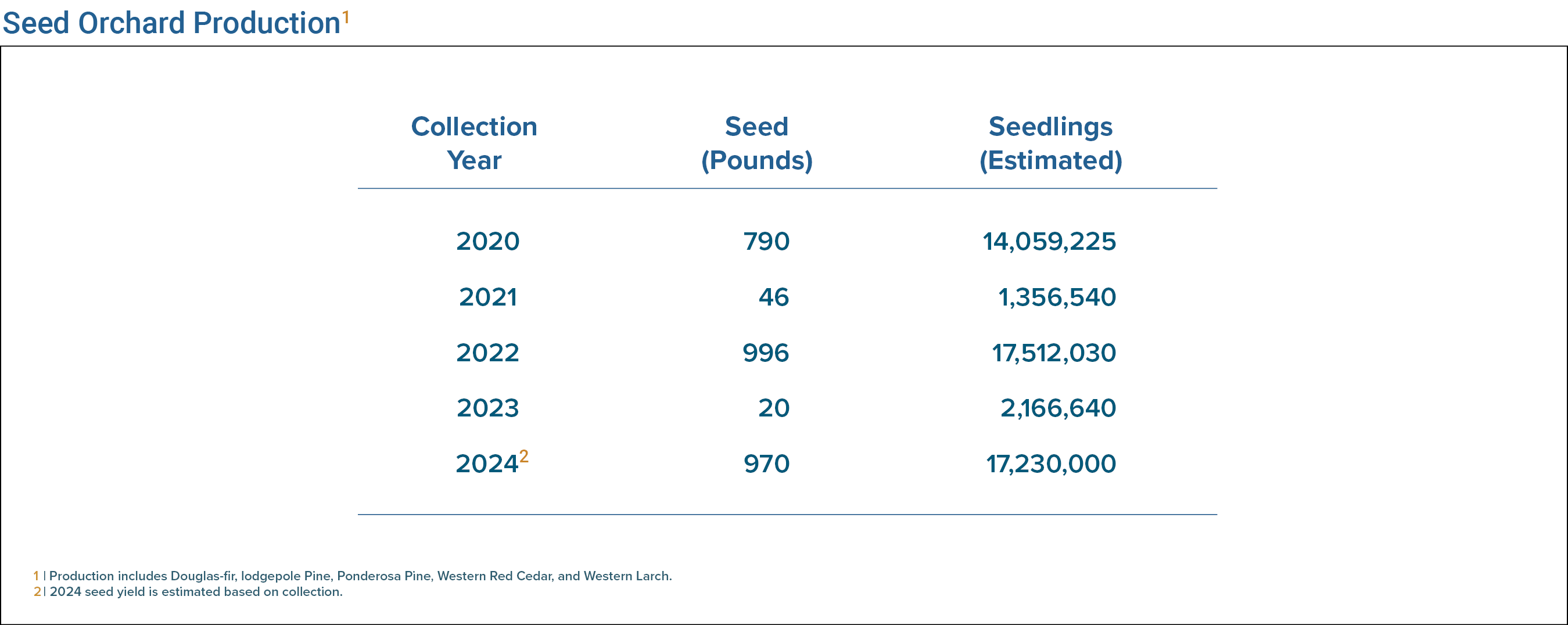

Within the orchard are several selected offspring, called families, of tree species native to North Idaho including Douglas-fir, Lodgepole Pine, Ponderosa Pine, Western Red Cedar, and Western Larch. Each tree in the orchard is identified with a tag that identifies their parent tree or family. Cones from each tree are collected and stored by family. This attention to detail enables seed to be custom blended, based on elevation zones, and seed needs for sowing of future seedlings. The benefit of using seed from improved trees is significant. Studies have shown this first-generation orchard improves growth approximately 10%-20% over seed collected from wild stands for Douglas-fir. Planting by elevation zone ensures trees are adapted to climatic conditions for each stand.

Because the grafted cuttings come from a source that is more mature, the seed orchard trees will produce cones in 10 years, which is much earlier than the typical 40 years in forest conditions. To increase seed production, trees are stressed using a combination of partial girdling and gibberellic acid inhibitors. Gibberellic acid, a hormone found in plants and trees, is important for cone production. Applying this hormone sends a signal to the tree, which causes it to produce cones. Partial girdling and gibberellic acid applications are done every three years, allowing the tree to rest for two years between each cone crop. Female flowers are open pollinated naturally from surrounding selected trees within the orchard. Even though the seed orchard is managed intensively for seed production, trees are cultured with fertilizer, watered regularly, and managed to maintain good health.

Cones are collected manually each August when seed is mature, but cones are not yet open. Collected cones are picked and stored separately by family and air dried for about a month at the orchard and then sent to a seed processor for seed extraction. Seed extraction uses heat to flare the cones, allowing the seed to fall out. Then, the seed is run across a series of screens of varying sizes to separate seed from cone residue and debris. The extracted seed is cleaned, surface dried, and freezer stored until used for sowing.

Each year, blended seed from a combination of families is sent to third-party nurseries for growing seedlings for the next planting season. To maximize seed usage and produce a viable seedling for planting in Idaho, seeds are sown into containers instead of in bareroot beds. Seedlings are typically grown in greenhouses which provide optimal growing conditions including light, temperature, and water. Fertilizer is custom blended and applied as required by growing seedlings. Typically, the mix will include nitrogen, potassium and phosphorous, along with trace elements to maintain good health. Within nine months, seedlings have reached ideal height and caliper, have a good bud set and a root system. At this time, they are ready to be lifted, bundled and boxed for freezer storage. Freezing the seedlings mimics the natural cycle of winter, which allows the seedlings to stay dormant during storage and shipping. This also helps prevent disease. Each March, foresters prepare their planting schedules and relay shipping orders to the nurseries so that seedlings can be removed and thawed for just-in-time deliveries to one of three Idaho cold storage facilities. After seedlings arrive at their destination cold storage facility, they are planted within a very short period. Planting in Idaho typically begins mid-April and finishes around Memorial Day.

Updating Our Forest Inventory

Forest inventory data serves as the foundation for decision-making. It influences everything from optimizing harvest schedules, deploying cost-effective silvicultural treatments, planning capital investments, modeling the sequestration of carbon, and adapting climate resilience strategies. Accurate, up-to-date forest inventory data enables PotlatchDeltic to plan for the future while remaining committed to sustainable forest management. The level of detail offers managers the ability to make critical decisions prioritizing the use of budgets and resources.

Field sampling serves specific goals during the cycle of a forest rotation. Measurements on young stands help inform survival rates and stocking. Data on merchantable stands provide insight into the size of trees and the ability to be grown into specific products. Many of these data help determine the need for silvicultural treatments, and the impact of treatments like thinning or fertilization. Long term datasets permit users to continue to refine and update modeled responses for growth and yield. These updates are crucial for understanding the forest dynamics of millions of acres, leading to higher confidence in the volume estimation used for future planning.

Traditional forest inventory practices rely on field crews collecting on-the-ground samples. Timber cruisers collect detailed measurements on heights, diameters, species, and quality to determine the biological characteristics of the stand to assess future growth more accurately. Measurement cycles range between 5 to 10 years, depending on the region and cover type. Field measurements present logistical challenges and are costly. Declines in the workforce and the difficult nature of inventory cruising in extreme environments have driven a need for technological advances to reduce field sampling.

PotlatchDeltic participates in numerous research partnerships across the country. Advancements in remote sensing, such as LiDAR and satellite imagery, are shifting the paradigm on how we approach forest management and inventory. Remote sensing provides us with information that enhances the value of traditional sampling data. It also provides valuable data for engineering and harvest planning, from identifying the optimal location for roads and log landings, to designing the best way to harvest a stand allowing us to minimize environmental impacts and reduce operating costs. By integrating cutting-edge inventory technology with traditional forestry expertise, we increase the long-term sustainability, climate resilience, and economic value of our forests and the communities that depend on them.

Idaho Tree Planting

On our Idaho timberlands, nothing beckons the awakening of the forest to spring like the sudden bustle of tree planting season. In six to eight weeks, roughly 6 million seedlings are planted across 15,000 acres of forestland. Planting is the culmination of an 18-month process that involves planning, preparation, and the growing of seedlings in the nursery. The climate and steep terrain in Idaho force this uniquely compressed tree planting window. To ensure high planting survival, seedlings must be planted into moist, warming soils with adequate time to grow new roots and become established on the site before the inevitable summer dry-down comes. The logistics are challenging, yet our foresters, contractors, and support staff do an excellent job ensuring the planting crews are just behind the snow as it recedes up the mountains in the spring.

Seedlings for spring planting are grown at several different nurseries located throughout the Pacific Northwest and southern British Columbia. Over 90% of our seedlings are from first-generation tree improvement programs and more than 70% of the seed is sourced at PotlatchDeltic’s own Cherrylane Seed Orchard. Seedlings must be thawed and then shipped to our cold storage buildings. Thirty to forty deliveries are planned and executed to keep seedlings on hand for the planting crews while minimizing the time between thawing and planting to improve seedling out-planting success. Planting inspectors are on site at every planting unit to make sure the operations plan is followed and to sample planting quality. At the peak of planting season in early May, over 200 people are actively involved in the planting program with more than 280,000 seedlings per day being planted-over one square mile planted in each day!

We recently undertook initiatives to decrease seedling stock size to lower growing, transportation, and planting costs and to reduce the inputs per seedling, including water, energy, soil, fertilizer, and packaging. We plant up to 6 different conifer species. Every tree species has evolved to fill an ecological niche in the forest, and we match those attributes to the conditions of the planting site. Each planting site is reviewed by our foresters and the appropriate species are selected with multiple species often planted in one planting unit. This process bolsters the diversity and resiliency of our timberlands, minimizing risks from climate and disturbance. Idaho’s steep and variable terrain limits planting operations to manual hand planting. Planters use either a shovel or hoedads to open a hole to mineral soil in which the seedling is planted. Planters carry the seedlings in tree bags they wear via a belt and suspenders with seedling holding compartments located on either hip. Each planter carries between 220 and 300 seedlings at a time - approximately 35 pounds.

High-quality, detailed planting is critical to the growth and survival of the seedlings - a seedling planted with minor error such as a crooked root or one planted too shallow with the root plug exposed will not survive. The critical job of planting the seedlings is done by contractors that rely on H-2B temporary labor visas to staff their crews. Companies must go through a heavily regulated process to get approval for the capped number of visas available. This includes the demonstration that the jobs are posted and available to American citizens but cannot be filled domestically. If contractors cannot secure sufficient H2-B visas, the seedlings grown the previous year may be wasted, and reforestation that is critical for regulatory, certification, environmental management, and wildlife may be delayed. Planting crews consist of one foreperson and typically 14 planters. A tree planter averages 1,700 seedlings planted per day - that is one seedling every 3.5 seconds for 8 hours. The work is hard, but you will not find a more pleasant group of people to work with than those reforesting our timberlands. We’ve built long-standing relationships with many of the planting companies, with some working with us for more than a quarter century. Many of the tree planters return for many seasons to plant seedlings on PotlatchDeltic timberlands and it’s great to see familiar faces and build relationships year after year.

Tree planting is one of the most important investments a timberland company undertakes, setting the stage for the future and ensuring all the benefits that forests provide are perpetuated.

Tree Planting in Arkansas

Every year in the U.S. South, we replant seedlings across areas harvested the previous 12-18 months. The primary goal of our reforestation program is to utilize the best planting stock possible. Our planting stock is selectively bred to achieve superior disease resistance, produce excellent form, exhibit high growth rates and be well-adapted to the local climate and growing conditions.

In Arkansas, we produce 30-40% of our seed at two PotlatchDeltic seed orchards. The orchards were established through a tree improvement co-operative in the early 2000s using parent trees with desirable characteristics. These orchards are open pollinated, which means pollen from any tree in the orchard can pollinate the seed. The seed-filled cones are harvested in October and are sorted and stored by family for form, cold hardiness, and growth. The remaining seed is acquired from third-party nurseries and comes from seed produced using open pollination and controlled pollination. Controlled pollination allows selection of both parent trees and provides additional improvement to planting stock. We do not utilize seedlings produced from genetic modification.

Seed is grown into seedlings at third-party nurseries. Seed is sent to nurseries in mid-February for a 45-day seed stratification process. The seed is planted in nursery beds in mid-April and the seedlings are lifted on an as needed basis starting in early December. Before lifting can occur at least 200 hours of chilling is required, where the ambient temperature is less than 32 degrees in the nursery. Seedlings are stored at 36-38 degrees to prevent freezing and to keep the tree dormant. The seedlings are then placed in bags or boxes for storage and transportation. All this careful handling is done to maintain healthy seedlings that will thrive when they are planted.

Planting season in the South starts in December and typically lasts 18 weeks, wrapping up by April. Planting can be accomplished by machine or hand planting. Machine planting is effective in challenging soils such as gravel, light rock, or deep sand. The machine planters are a 2-person operation and plant approximately 12 acres per day per machine. Hand planting is used on sites that have undergone a mechanical site preparation to create elevated beds. Planting is done by contractors who typically hire H-2B guest workers. These professional tree planters tend to return year after year and are highly efficient and skilled. Crews of 10-15 planters each plant up to 3,000 seedlings per day or around 10 seconds per tree! Inspectors stay close behind the planters to ensure quality planting performance and proper seedling density. Foresters conduct checks as the seedlings grow to track growth and survival.